China Best Ar Coated Window Manufacturers Suppliers – Polished Transparent Synthetic Sapphire Windows – Optic-Well

China Best Ar Coated Window Manufacturers Suppliers – Polished Transparent Synthetic Sapphire Windows – Optic-Well Detail:

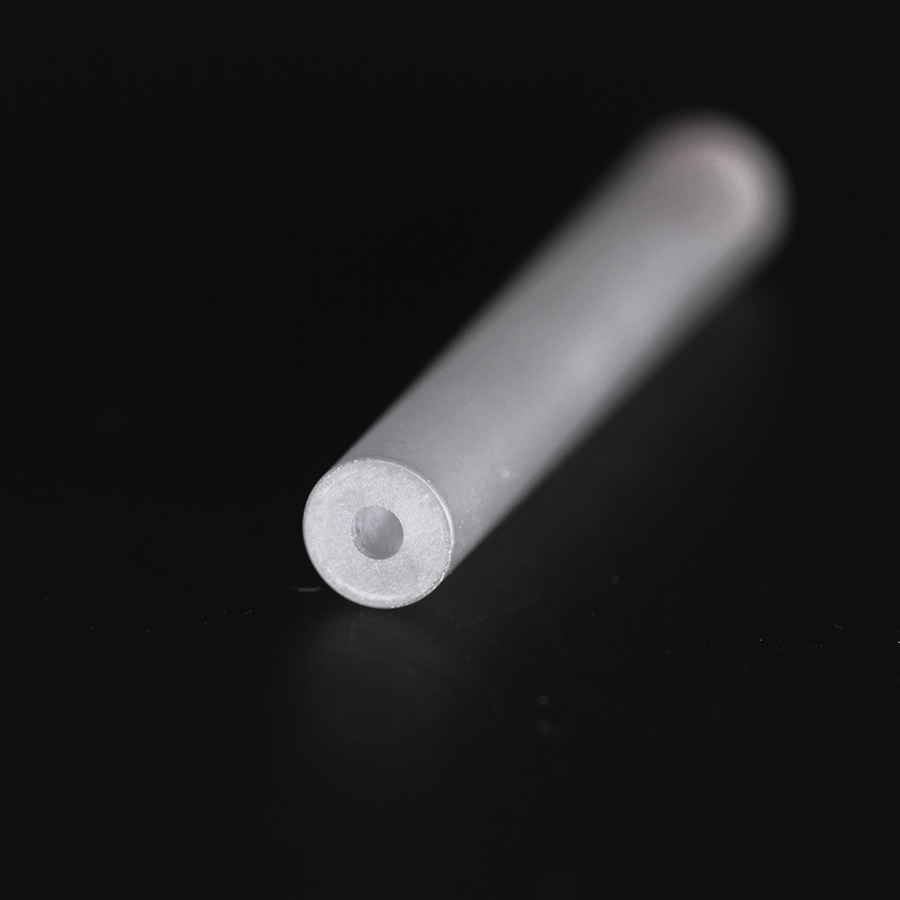

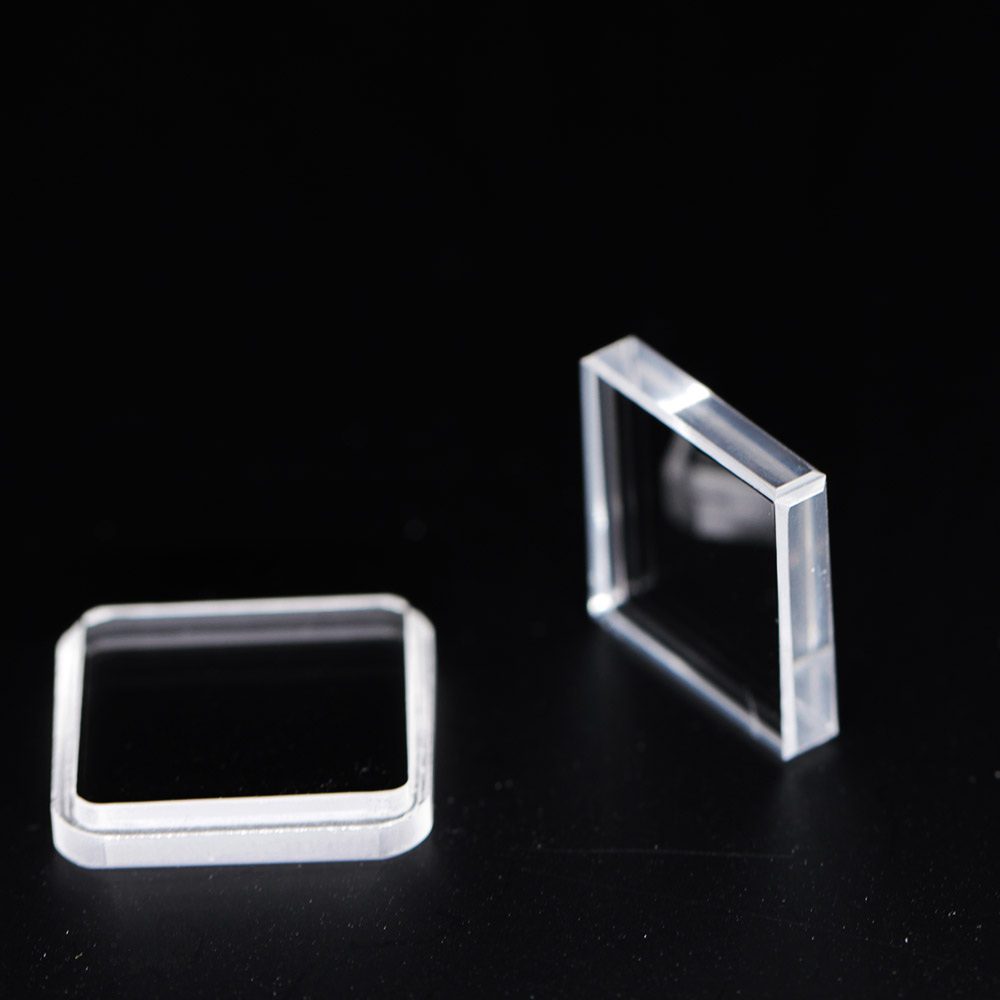

Sapphire window is one of the most hardest optical window in the world. It was widely used as Sight Windows / Lens Cover/ Viewport Windows / Laser Windows / Sports Equipment / Touch Screen to protect precision sensors , screen plant and people from harsh conditions and situations.

Sapphire is a form of alumina (commonly known as alumina (α-alumina) or alumina) and is one of the most abundant compounds in nature. Naturally, alumina (Al2O3) is a white powdered material widely used as an industrial abrasive. When heated to approximately 2050 degrees ℃(nearly 4000 degrees F°), the powder melts and a single crystal can then be formed using any of several crystal growth methods. We are using Kyropoulos Sapphire(KY Sapphire).

Thanks to Sapphire’s superior hardness specification(Moh’s 9 ), it almost can’t be scratched by any natural materials but be only ground by diamond(Moh’s 10). This means it allows use your equipment with sapphire window in any harsh working conditions without extra protection for them.

As an ideal optical window material, of course it must be very good in light transmission performance, Sapphire crystal has good light transmission performance, and its light transmission range is 0.15~7.5 microns, covering ultraviolet, visible, near-infrared, mid-infrared and other wavebands. In most applications, the surface of the sapphire window is not coated for use, , coating will make the surface scratched easily.

Besides the outstanding hardness, sapphire also have plenty advantages. Here we list some Basic-Properties for your inference:

1.Maximum Useful Temperature ≈2000°C

2.Transmission Rate Of Visible Light: Around 90% ( Uncoated )

3.Only Attacked By Boiling Hydrofluoric Acid.

Product detail pictures:

Related Product Guide:

Bear "Customer first, High quality first" in mind, we perform closely with our consumers and provide them with efficient and experienced services for China Best Ar Coated Window Manufacturers Suppliers – Polished Transparent Synthetic Sapphire Windows – Optic-Well , The product will supply to all over the world, such as: Georgia, Swiss, Uzbekistan, Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work whole-heartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.