China Best Fiber Optic Window Quotes Pricelist – Sapphire Window For Flame Detector – Optic-Well

China Best Fiber Optic Window Quotes Pricelist – Sapphire Window For Flame Detector – Optic-Well Detail:

Flame detector is a type of sensor that can detect and respond to the presence of a flame. These Detectors have the ability to identify smokeless liquid and smoke that can create open fire. It’s easy to find flame detectors are exist in industrial warehouses, chemical production plants/stores, petrol storage and pump stations, power plants, transformer stations and many other place need to avoid open fire.

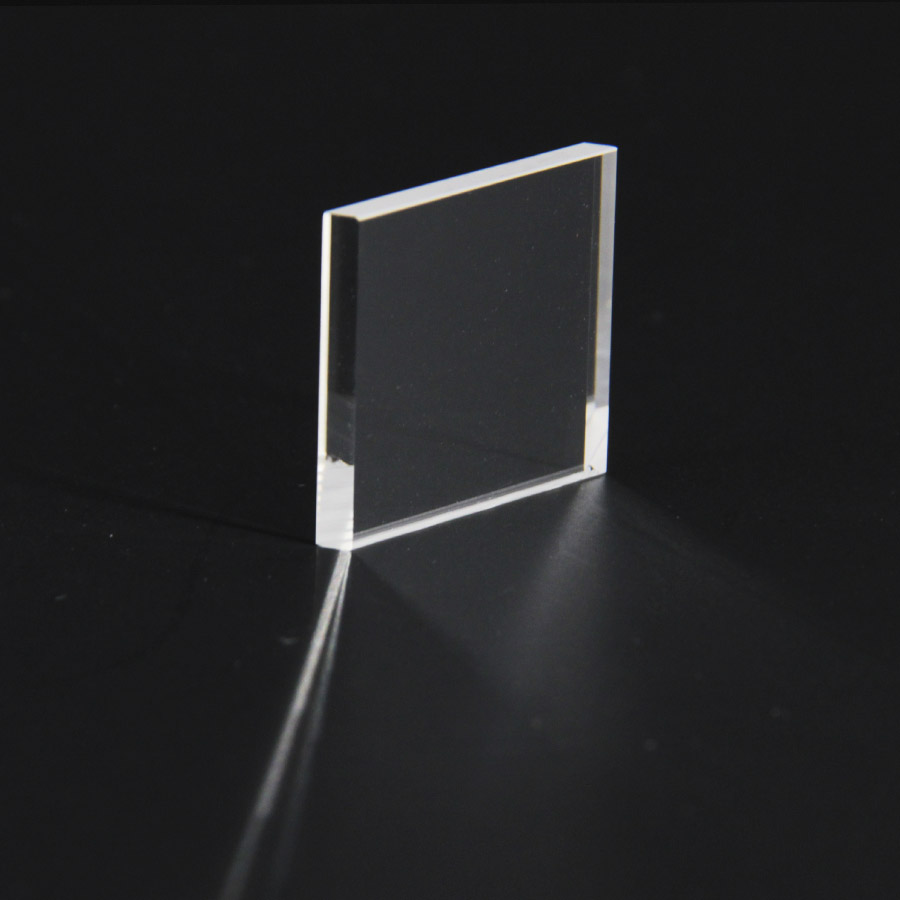

In all the components of flame detector, the window is the main component that exists as a protection for the sensor but does not affect the normal operation of the sensor, generally using BK7, Sapphire, Float glass, Quartz and other materials. However, because flame detector generally works in a special working environment, may face corrosive gases, high temperature, high heat, friction and other harsh working conditions, so sapphire may be the most ideal window material in terms of characteristics.

Here are basic properties of sapphire materials, you can easily find out why it is the ideal materials for covers.

.Transmission percentage of different light frequency. (Uncoated)

Visible Light: >85%

Infrared: 85% (0.75~4μm);70%(4.7μm);50%(5.2μm)

Ultraviolet: 80% (0.4~0.3μm); 60%(0.28μm);50%(0.2μm)

.Hardness: Mohs 9 , Knoop≥1700kg/mm²

Due to the excellent mechanical strength and friction resistance, the window can be thinned without meeting the same properties as other types of glass

.Thermal Expansion: 6.7 x 10-6 // C-axis.

.No attacked by acid or alkalis ,only attacked by HF at 300℃.

If you have any further questions about sapphire material and custom sapphire windows, welcome to contact us.

You can also download the properties of sapphire by click the following links. Sapphire Properties.

Product detail pictures:

Related Product Guide:

We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for China Best Fiber Optic Window Quotes Pricelist – Sapphire Window For Flame Detector – Optic-Well , The product will supply to all over the world, such as: Qatar, Macedonia, Luxembourg, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.