China Best Rife Machine Plasma Tube Manufacturers Suppliers – Sapphire Tube For Plasma Application – Optic-Well

China Best Rife Machine Plasma Tube Manufacturers Suppliers – Sapphire Tube For Plasma Application – Optic-Well Detail:

Though Diamond is the hardest material, but it is almost impossible to make diamond tubes and rods. So Sapphire became the best choice making durable tubes and rods. Sapphire tubes can be used in harsh environments to house sensitive sensors and protect them from pressure and mechanical abuse. Sapphire tube is the best high-pressure vessel and transportation pipeline for many high-pressure systems. The sapphire tube can withstand extreme pressure while allowing safe observation and spectral analysis of fluids and gases.

In normal situation the thinnest wall thickness of sapphire tube we can make is above 2mm. As it’s longer the thickness is request to be more than 2mm. The tube wall can be chosen to be polished(Transparent) or just as all fine ground(Cloudy), as some technical bottlenecks have not yet been broken through, our company’s technical staff can only achieve the standard of polishing and translucent when polishing the cylindrical surface. Flat surfaces on the top can be highly polished with good surface flatness.

Here we established some typical products we made for other customers before.

Large Polished Sapphire Tube:

1. Dimensions: OD38±0.1 x ID25±0.1mm

2. Length: 150±0.1mm

3. Material: Optical Grade Sapphire(KY Method), No Defections Inside.

4. Surface Quality: Round Surface Polished Transparent.

5. Chamfer: 0.5x 45°

Top & Bottom Polished Sapphire Tube

1. Dimensions: OD15±0.05 x ID10±0.05mm

2. Length: 20±0.1mm

3. Material: Optical Grade Sapphire(KY Method), No Defections Inside.

4. Surface Quality: Top & Bottom Polished S/D 60/40, Round Surface Fine Ground.

5. Chamfer: 0.2x 45°

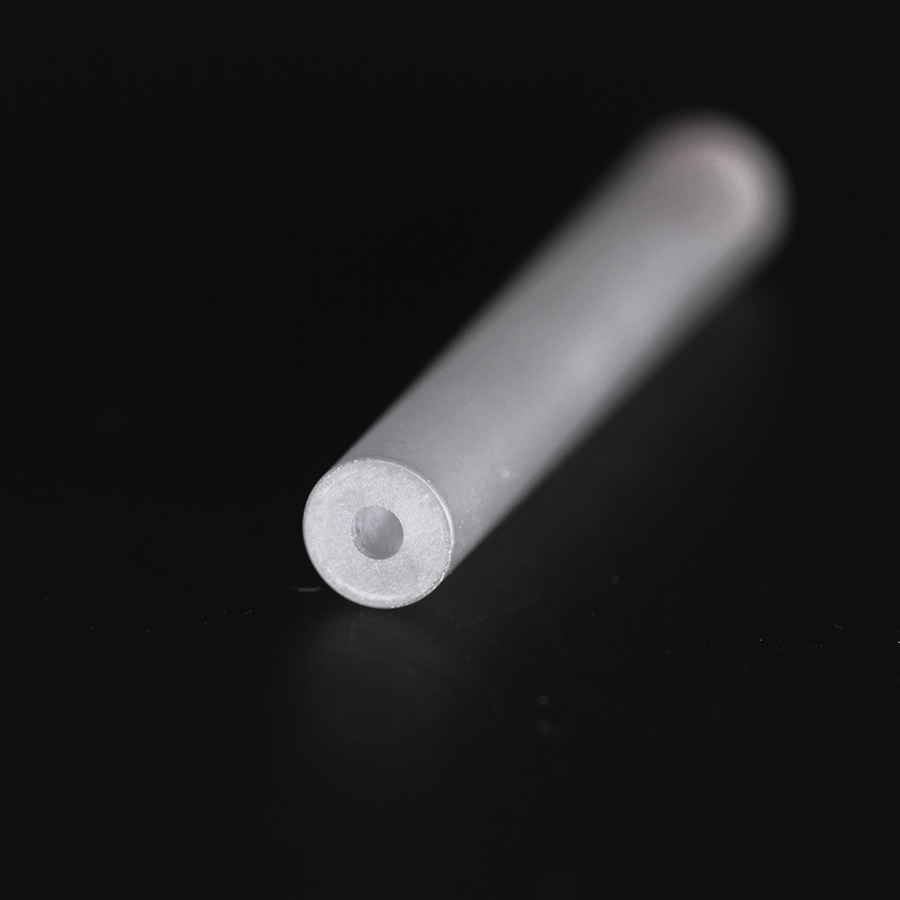

All Polished Transparent Sapphire Tube

1. Dimensions: OD2±0.05 x ID1.6±0.05mm

2. Length: 25±0.1mm

3. Material: Optical Grade Sapphire(KY Method), No Defections Inside.

4. Surface Quality: Top Polished S/D 60/40, Round Surface Polished Transparent.

5. Chamfer: 0.2x 45°

Product detail pictures:

Related Product Guide:

Our pursuit and company intention is usually to "Always fulfill our purchaser requirements". We go on to acquire and layout excellent high quality products for both our previous and new consumers and realize a win-win prospect for our customers too as us for China Best Rife Machine Plasma Tube Manufacturers Suppliers – Sapphire Tube For Plasma Application – Optic-Well , The product will supply to all over the world, such as: Greek, Malaysia, Munich, Due to our good products and services, we have received good reputation and credibility from local and international customers. If you need more information and are interested in any of our products, please feel free to contact us. We look forward to becoming your supplier in the near future.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!