China High-Quality Sapphire Plasma Tube Quotes Pricelist – Optical Sapphire Crystal Rod Lens – Optic-Well

China High-Quality Sapphire Plasma Tube Quotes Pricelist – Optical Sapphire Crystal Rod Lens – Optic-Well Detail:

Sapphire Rods can be used as Rod lenses, Plunger, Bearings, Wire Guide, ETC.

Why more and more customers choose sapphire today? Not only because of the hardness grade of sapphire, also the superior Physical properties and Mature Technology.

| Optical Properties | |

| Refractive Index | 1.769//C-axis,1.760±C-axis at 0.5893μm |

| Visible Light | >85% Excellent |

| Infrared | 85% 0.75~4μm,70% 4.7μm, 50% 5.2μm |

| Ultraviolet | 80% 0.4~0.3μm,60% 0.28μm, 50% 0.2μm |

| Mechanical Properties | |

| Mohs‘ Hardness | Mohs9,Knoop≥1700kg/mm2 |

| Modulus of Elasticity | 3.5×106~3.9×106 kg/cm2 |

| Compressive Strength | 2.1x104kg/cm2 |

| Tensile Strength | 1.9x103kg/cm2 |

As Sapphire was Lab-Created in 1916, Sapphire and sapphire tooling method became widely used and more cheaper than the time it’s born. From the Ingot to Rods there are several steps:

Crystal Growingà OrienteeringàDrillingàCuttingàRoundingàGrindingàPolishing.

Sapphire Rods are likely to use as wear resistant accessories more widely, but as human technology expanding, sapphire rod lens will take more place in the future. Rod lens is polished on the circumference and ground on both ends. Optical performance is similar to a cylinder lens. Collimated light passing through the diameter of the rod will be focused into a line. The addition of this product line is part of a continued effort to support current trends toward miniaturization.

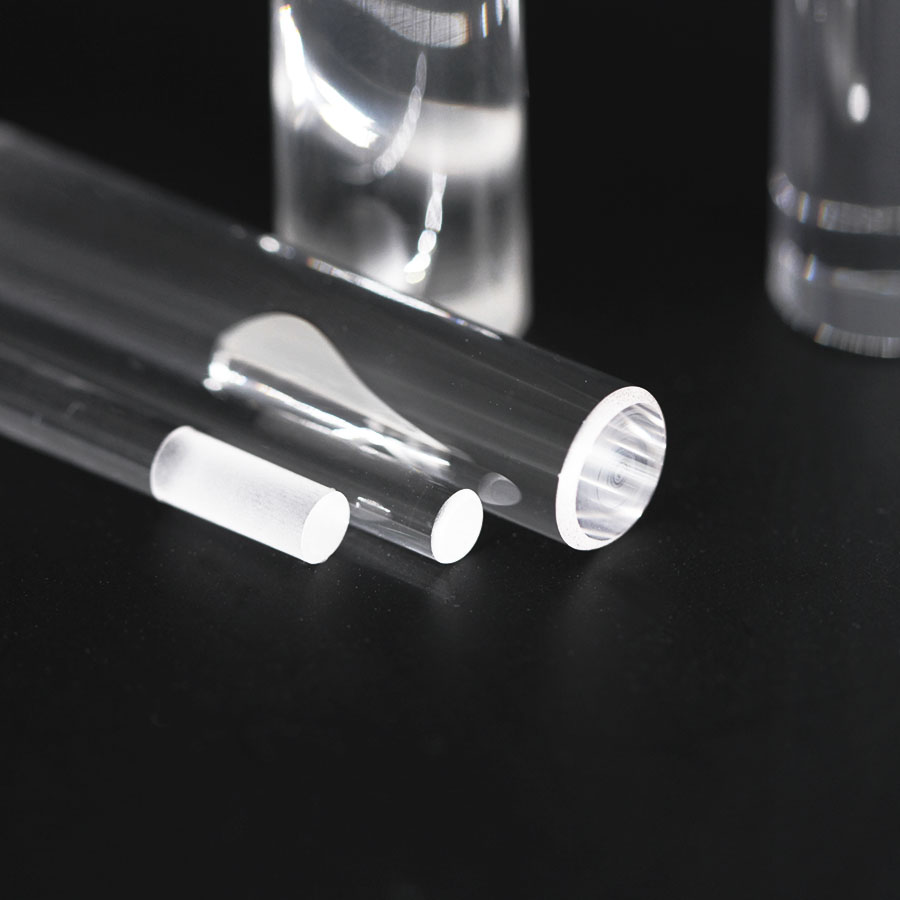

Typical Sapphire Rods.

Raw Sapphire Rods: All fine Ground (Cloudy Surfaces)

Sapphire Rod Lens: Top & Bottom Optical Polished Best Surface Flatness Up to λ/10 @633nm

Sapphire Corn Rod: Any Degree, One/Two Ends. Ground/Polished, Customized By Client.

Domed Sapphire Rod: One/Two Ends Domed, Ground/Polished, Customized By Client.

All Transparent Sapphire Rods: Cylinder Surface Polished Transparent, Top & Bottom Optical Polished

Product detail pictures:

Related Product Guide:

We persist with the principle of "quality 1st, assistance initially, continual improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for China High-Quality Sapphire Plasma Tube Quotes Pricelist – Optical Sapphire Crystal Rod Lens – Optic-Well , The product will supply to all over the world, such as: Uzbekistan, Algeria, Montpellier, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers' faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end goods, to do experienced products and solutions.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.