High Quality Stocked Nd:YAG Laser Crystal Rods

Nd:YAG Laser Crystal Rods

.Introduction:

Nd:YAG rod (neodymium-doped YAG): Nd:YAG is a common laser gain medium with neodymium ions (Nd3+) as the dopant. When pumped with a suitable light source, it mainly emits lasers at a wavelength of 1064 nanometers (nm) in the near-infrared spectrum. Nd:YAG lasers have powerful and flexible properties, making them one of the most versatile lasers. They are capable of producing high output power in both continuous wave and pulse modes, giving users the option to choose the best mode for their specific application. In addition, the infrared output of Nd:YAG lasers can be absorbed by a wide range of materials. This, combined with the high power output, makes Nd:YAG lasers the first choice for many industrial applications such as cutting, welding, and drilling.

.Nd:YAG and Nd:Ce:YAG:

Nd:YAG (neodymium-doped yttrium-aluminum garnet) and Nd:Ce:YAG (neodymium-cerium-doped yttrium-doped aluminum garnet) are two similar laser gain media used in solid-state lasers. The main difference between them is the specific doping elements added to the YAG crystal matrix, resulting in some differences in performance.

. Nd:YAG (neodymium-doped YAG): Nd:YAG is a common neodymium ion (Nd3+) as a dopant. Nd:YAG lasers are known for their high power and high efficiency, are suitable for a wide range of laser operating modes, and are able to operate at high average power, which is widely used in fields such as cutting, welding, engraving, and medical procedures.

. Nd:Ce:YAG (neodymium-doped YAG): Nd:Ce:YAG is a variant of Nd:YAG crystals to which cerium ions (Ce3+) are also added as a dopant. The addition of cerium ions can change the properties of the crystal, making it have the characteristics of anti-ultraviolet radiation, good thermal stability, low thermal distortion, high output efficiency and good beam quality.

The choice between Nd:YAG and Nd:Ce:YAG for a specific laser application depends on the desired laser parameters and application requirements. Usually we need to think about

1. Energy and power; 2. Efficiency; 3. Cost; 4. Specific application requirements, such as requirements for beam quality or pulse energy.

Therefore, how to choose the right material also needs to be analyzed by engineers in practical applications, and we are very welcome to ask you about the specific parameters of our products to help you better choose the required materials.

Advantages:

- .High gain, low threshold, high efficiency

- .1064nm light wave has less absorption, high optical quality and low loss

- .High mechanical strength, good thermal conductivity and thermal shock characteristics

- .Suitable for various laser operating modes (continuous, pulsed, Q-switch, mode-locked, frequency doubling, etc.)

- .Suitable for high average power solid-state lasers

Pump transition wavelength, λp (nm): 808nm

Laser transition wavelength, λl (nm): 1064nm

Stimulated emission area: 2.8x10-19 cm2

Photon energy: 1.86 x 10-19 J@1064nm

Emission linewidth: 4.5A @1064nm

Emission cross section(Nd1 at %): 2.7~8.8 x 10-19cm2

Fluorescence lifetime(Nd1 at %): 230μs

Index of refraction: 1.8197@1064nm

Crystal Structure: Cubic

Lattice Constants: 12.01 A

Density: 4.56 ± 0.04g/cm³

Melting Point: 1950 °C

Refractive Index: n= 1.8197 at 1064nm

Thermal Conductivity -(W/Cm/K(@25°C): 0.14 W

Specific Heat- (J/g.Cm³): 0.59

Thermal Expansion /(10-6 /°C(@25°C) ): 6.9

Hardness (Mohs): 8.5

Young`s Modulus /GPa: 317

Shear Modulus / GPa: 54.66

Extinction Ratio: 25dB

Poisson Ratio: 0.25

Solubility: Insoluble in water / Slightly soluble in common acid.

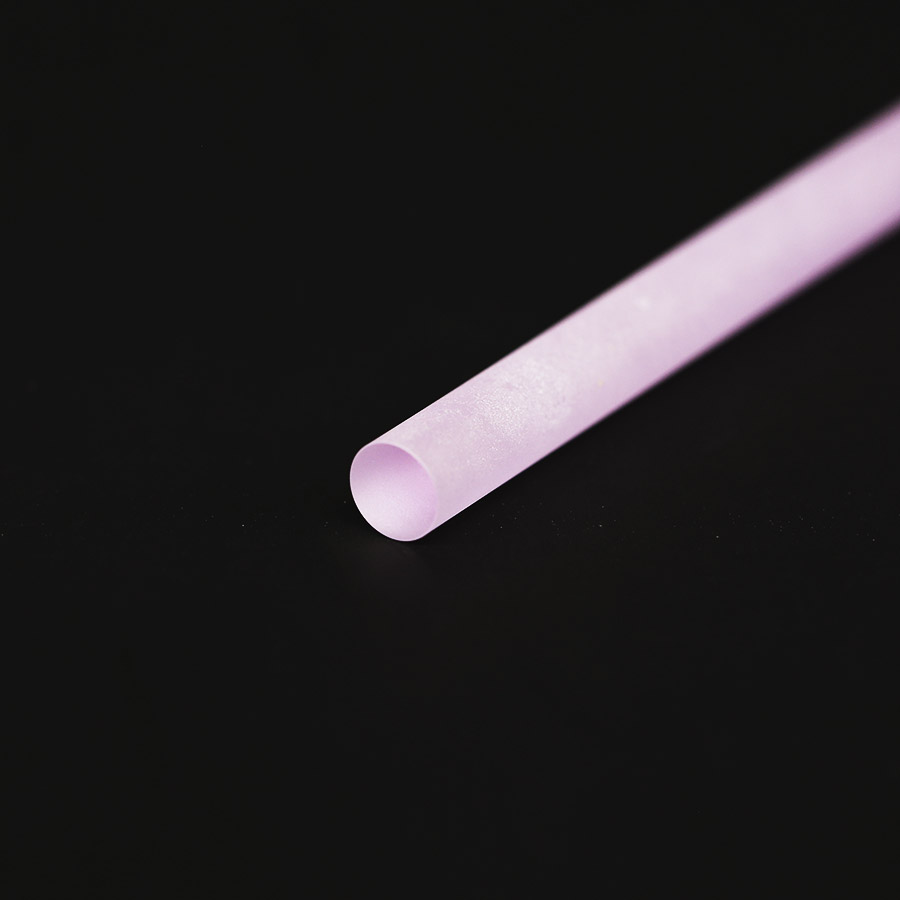

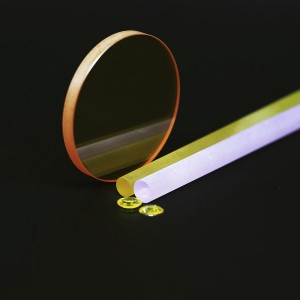

Diameter x Length/ Material :Nd:YAG / Pink Color

D3x65mm - Both ends polished B grade / A grade/ S grade

D5x85mm - Both ends polished B grade / A grade/ S grade

D6x 120mm - Both ends polished B grade / A grade/ S grade

D6x 145mm - Both ends polished B grade / A grade/ S grade

D7x 100mm - Both ends polished B grade / A grade/ S grade

D7x 120mm - Both ends polished B grade / A grade/ S grade

D7x 145mm - Both ends polished B grade / A grade/ S grade