Optical Sapphire Window

.Optical Sapphire Window

Introductions:

About Sapphire Materials:

Kyropolis method (KY) sapphire benefits from nearly 20 years of vigorous development, in the crystal size and quality has made rapid progress, the current market conditions ky sapphire is the most widely used sapphire window material, although EFG method of production of sapphire plate can reach larger size, but the main market for consumer products , the sapphire windows are mostly under D100mm size. Our sapphire material is mainly KY sapphire,With A, C, M -Axis. If you have larger sapphire window size needs, Please contact us.

Our Processing Capacity:

.Dimensions and Tolerance: In order to accommodate the assembly of the window, our highest dimensional tolerances can be achieved with +0.005/-0 (outer diameter), ± 0.02 (inner diameter), and our default tolerance is ±0.1mm - (tight tolerance will increase the cost while we thinking the quotation.)

.Surface Quality: Per MIL-PRF-13830B, It is a contrasting representation of scratches and dots on the surface of an optical window. We offer different surface quality standard: S/D 80/50(Standard), S/D 60/40(Normal) , S/D 40/20(High), S/D 20/10(Very High) -(Higher Surface Quality will increase the cost while we thinking the quotation.)

.Surface Flatness: We use reflected wave surface accuracy to measure the flatness of the product, PV can be best as λ/20@633nm,but the best PV will effect by the thickness and dimensions, please contact us if you have any request for PV or RMS.

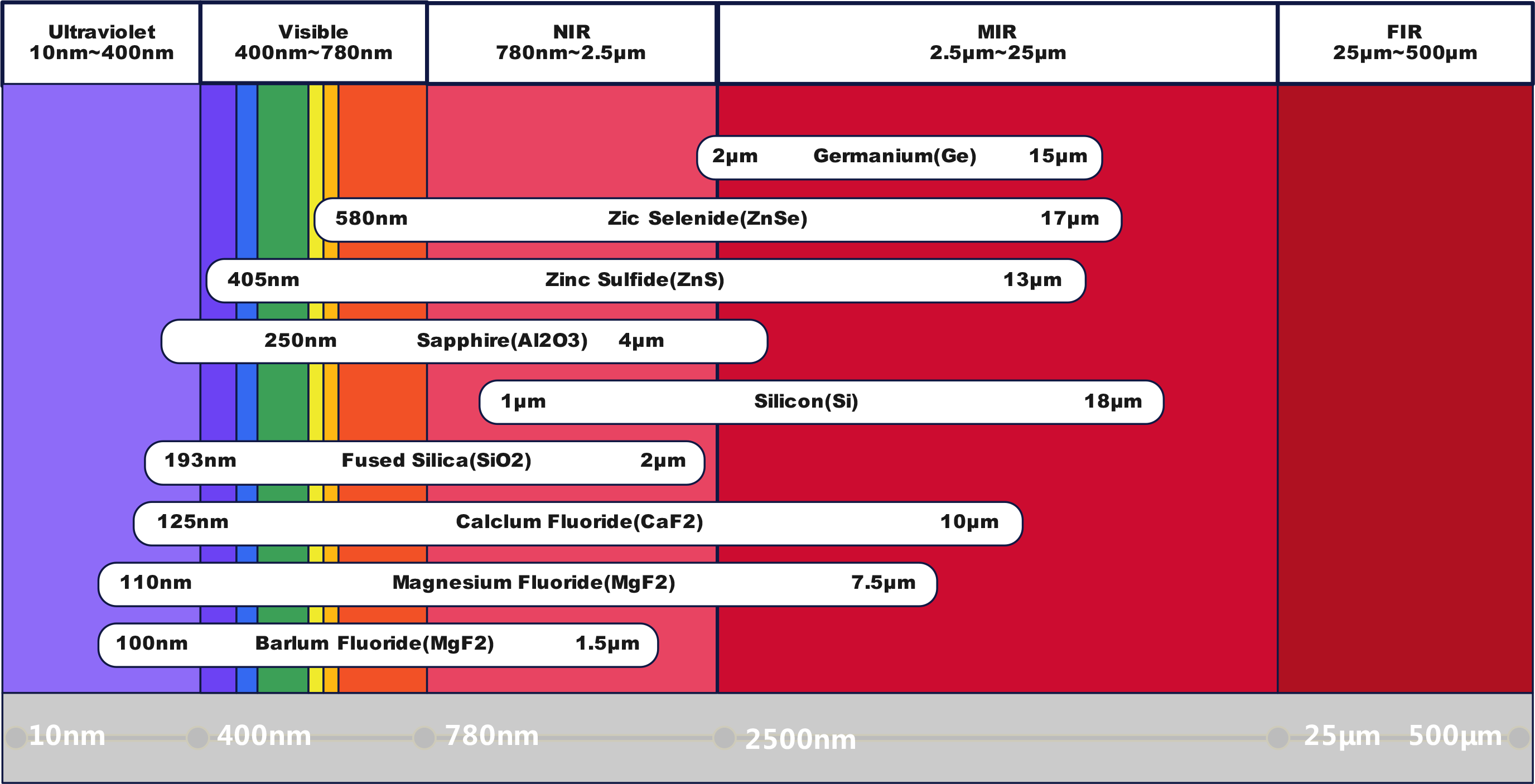

.Light Transmission Frequency Comparison With Other Optical Materials

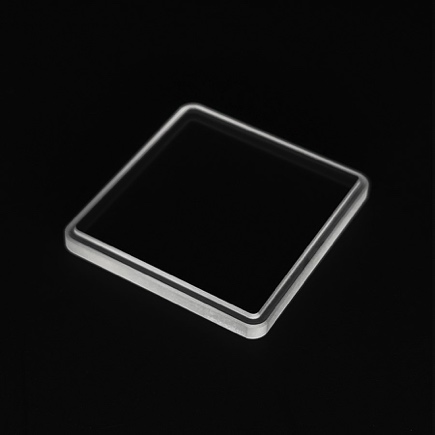

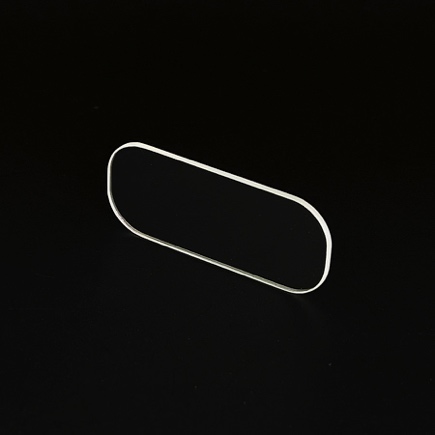

Typical Shapes:

Crystal Structure: Rhombohedra Hexagonal Single Crystal

Chemical Composition: Al2O3

Common Purity: 99.99%~99.999%

Specific Gravity: 3.99~3.98

Mohs‘ Hardness: Mohs9

Knoop Hardness: Knoop≥1700kg/mm2

Modulus of Elasticity: 3.5x106~3.9x106 kg/cm2

Compressive Strength: 2.1x104kg/cm2

Tensile Strength: 1.9x103kg/cm2

Melting Point: 2050°C

Softening Point: 1800°C

Specific Heat: 0.18(at 25°C)

Thermal Expansion: 6.7x10-6// C-axis 5.0x10-6±C-axis

Acids and Alkalis Attack: No attacked by acid or alkalis,Attacked by HF at 300°C

Dielectric Constant: 7.5~10

Electrical Resistivity: 1011Ω/cm at 500°C,106Ω/cm at 1000°C 103Ω/cm at 2000°C

Refractive Index: 1.769//C-axis,1.760±C-axis at 0.5893μm

Visible Light: >85% Excellent

Infrared:85% 0.75~4μm,70% 4.7μm, 50% 5.2μm

Ultraviolet:80% 0.4~0.3μm,60% 0.28μm, 50% 0.2μm